Material Requirements Planning (MRP) software stands at the forefront of modern business operations, orchestrating the intricate dance of resources, production schedules, and demand forecasting. In this comprehensive exploration, we will delve into the world of MRP software, unraveling its history, dissecting its key features, and examining its impact across diverse industries.

I. Introduction

A Brief Overview of MRP Software

MRP software, an acronym for Material Requirements Planning, serves as the linchpin of efficient production and resource management. At its core, MRP software is a system designed to streamline the complex processes involved in manufacturing, ensuring that businesses have the right materials at the right time to meet production demands.

Evolution and Importance in Modern Business

The evolution of MRP software mirrors the dynamic landscape of business operations. From its humble beginnings to its current state of technological sophistication, MRP software has become an indispensable tool for businesses aiming to optimize their production processes, reduce costs, and enhance overall efficiency.

II. Understanding MRP

Definition of MRP (Material Requirements Planning)

At its essence, Material Requirements Planning (MRP) is a systematic approach to managing the procurement and use of materials in the manufacturing process. MRP software takes this concept to the next level by automating and integrating these processes, providing real-time insights and control.

Core Components of MRP Systems

To understand the power of MRP software, it’s essential to grasp its core components. From inventory management to production scheduling and demand forecasting, MRP systems bring a holistic approach to resource planning, ensuring a synchronized flow of materials and resources.

III. Historical Perspective

Origins and Development of MRP

The roots of MRP trace back to the mid-20th century when manufacturers sought a more systematic approach to manage their production processes. The early iterations of MRP were rudimentary compared to today’s sophisticated software solutions, but they laid the foundation for a revolution in manufacturing efficiency.

Milestones in MRP Software Evolution

As technology advanced, so did MRP software. The integration of computing power in the 1970s marked a turning point, allowing for more complex calculations and data processing. Subsequent decades witnessed the integration of graphical interfaces, database systems, and the evolution towards the comprehensive Enterprise Resource Planning (ERP) systems we see today.

IV. Key Features of MRP Software

Inventory Management

One of the primary functions of MRP software is meticulous inventory management. By maintaining a real-time record of stock levels and consumption rates, businesses can avoid stockouts, overstock situations, and ensure a smooth production flow.

Production Scheduling

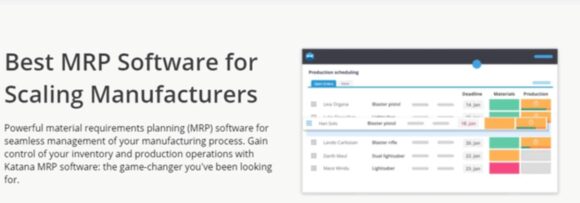

Efficient production scheduling is the heartbeat of any manufacturing operation. MRP software optimizes production schedules by aligning them with demand forecasts, resource availability, and delivery timelines, thereby reducing lead times and improving overall production efficiency.

Bill of Materials (BOM)

A critical aspect of manufacturing is the Bill of Materials (BOM), a comprehensive list of components, sub-assemblies, and raw materials required for a specific product. MRP software automates the creation and management of BOMs, ensuring accuracy and consistency in the production process.

Demand Forecasting

Accurate demand forecasting is the cornerstone of effective resource planning. MRP software utilizes historical data, market trends, and advanced algorithms to predict future demand, enabling businesses to adjust their production schedules and inventory levels accordingly.

V. Benefits of Implementing MRP Software

Improved Efficiency and Productivity

Implementing MRP software translates into tangible improvements in efficiency and productivity. By automating repetitive tasks, reducing manual errors, and providing real-time insights, businesses can operate more smoothly and respond swiftly to changes in demand or production schedules.

Cost Reduction and Resource Optimization

Cost-conscious businesses find a valuable ally in MRP software. Through precise inventory management, optimized production scheduling, and demand-driven resource allocation, MRP software contributes to significant cost reductions and efficient use of resources.

Enhanced Decision-Making

In the fast-paced world of modern business, informed decision-making is crucial. MRP software provides decision-makers with a comprehensive view of the production landscape, empowering them to make strategic choices that align with business goals and market dynamics.

VI. Common Challenges in MRP Implementation

Integration Issues

The implementation of MRP software is not without its challenges. Integration with existing systems, such as accounting or customer relationship management (CRM) software, can pose hurdles that require careful navigation.

Data Accuracy and Consistency

The old adage “garbage in, garbage out” holds true for MRP systems. Ensuring the accuracy and consistency of data input is paramount for the effective functioning of MRP software. Even small discrepancies can lead to significant disruptions in production.

Employee Resistance

The introduction of new technology often faces resistance from employees accustomed to existing processes. Overcoming this resistance requires thoughtful change management, training programs, and transparent communication about the benefits of MRP software.

VII. MRP Software vs. ERP Systems

Distinguishing Features

While MRP software focuses on the intricacies of material requirements and production planning, Enterprise Resource Planning (ERP) systems encompass a broader spectrum of business processes. Understanding the distinctions between the two is crucial for businesses seeking the right solution for their needs.

Choosing the Right System for Your Business

The choice between MRP software and ERP systems depends on the scale, complexity, and goals of a business. Small to medium-sized enterprises may find MRP software sufficient, while larger enterprises with multifaceted operations might opt for the comprehensive functionalities of ERP systems.

VIII. Case Studies

Success Stories of Businesses Using MRP Software

Real-world examples of businesses reaping the benefits of MRP software shed light on its practical impact. Case studies provide insights into how MRP software has transformed operations, improved efficiency, and contributed to the success of various enterprises.

Lessons Learned from MRP Implementation Failures

Not every implementation of MRP software is smooth sailing. Analyzing instances where businesses faced challenges and setbacks offers valuable lessons for others considering or undergoing MRP implementation.

IX. Future Trends in MRP Software

AI and Machine Learning Integration

The future of MRP software lies in the seamless integration of artificial intelligence (AI) and machine learning (ML). These technologies enhance predictive capabilities, enabling more accurate demand forecasting, intelligent decision support, and proactive issue resolution.

Cloud-Based MRP Solutions

The cloud has revolutionized how businesses approach software solutions. Cloud-based MRP systems offer flexibility, scalability, and accessibility, allowing businesses to manage their operations from anywhere with an internet connection.

Sustainability and MRP

In an era where sustainability is a paramount concern, MRP software is evolving to address environmental considerations. Integrating sustainability metrics into the decision-making process ensures that businesses align their operations with eco-friendly practices.

X. Selecting the Right MRP Software for Your Business

Factors to Consider

Choosing the right MRP software requires a careful evaluation of various factors, including the size of the business, industry requirements, scalability, user-friendliness, and integration capabilities with existing systems.

Top MRP Software Providers in the Market

An overview of leading MRP software providers gives businesses a starting point in their search. Understanding the strengths and weaknesses of different solutions helps in making an informed decision.

XI. Implementation Strategies

Best Practices for Seamless Integration

A successful MRP implementation goes beyond selecting the right software. Best practices for seamless integration involve thorough planning, collaboration between departments, and a phased approach to minimize disruptions.

Training and Change Management

The human element is critical in MRP implementation. Training programs and change management strategies ensure that employees embrace the new technology, maximizing its benefits without disrupting daily operations.

XII. MRP Software in Different Industries

Manufacturing

In the manufacturing sector, MRP software is a game-changer, optimizing production processes, reducing waste, and ensuring timely delivery of products.

Retail

In the retail industry, MRP software aids in inventory management, demand forecasting, and supply chain optimization, contributing to a more responsive and efficient operation.

Healthcare

The healthcare industry benefits from MRP software in managing medical supplies, pharmaceuticals, and equipment, ensuring the availability of resources when needed.

Aerospace

Aerospace manufacturers rely on MRP software to coordinate the intricate supply chain involved in producing complex aerospace components, from raw materials to final assembly.

XIII. Regulatory Compliance and MRP

Meeting Industry Standards

Compliance with industry standards and regulations is non-negotiable. MRP software plays a crucial role in ensuring that businesses adhere to the necessary standards in their respective industries.

Navigating Legal and Regulatory Requirements

As regulations evolve, businesses must stay agile in adapting their MRP systems to meet new legal and regulatory requirements. Failure to do so can result in fines, legal issues, and damage to reputation.

XIV. MRP Software and Supply Chain Management

Synergy Between MRP and SCM

The synergy between MRP software and Supply Chain Management (SCM) is evident in their shared goal of optimizing processes and ensuring the seamless flow of materials from production to delivery.

Addressing Supply Chain Disruptions

In a world where supply chain disruptions are becoming more frequent, MRP software equips businesses with the tools to identify risks, develop contingency plans, and navigate unforeseen challenges.

XV. Real-Time Data in MRP

Importance and Impact on Decision-Making

Real-time data is the lifeblood of MRP software. Its importance lies in empowering decision-makers with up-to-the-minute insights, enabling them to make informed choices that directly impact the bottom line.

Overcoming Challenges in Real-Time Data Integration

Challenges in integrating real-time data include ensuring data accuracy, minimizing latency, and addressing potential system vulnerabilities. Overcoming these challenges is crucial for harnessing the full power of MRP software.

XVI. Customization and Scalability

Tailoring MRP Software to Specific Business Needs

The one-size-fits-all approach doesn’t apply to MRP software. Customization is key to aligning the software with the unique needs and processes of each business, ensuring optimal performance.

Adapting to Business Growth

Scalability is another vital aspect of MRP software. As businesses grow, MRP systems must seamlessly adapt to increased data volume, user numbers, and evolving operational complexities.

XVII. Security Concerns in MRP Systems

Data Security Measures

As businesses entrust sensitive information to MRP systems, robust data security measures are imperative. Encryption, access controls, and regular security audits are essential components of a secure MRP environment.

Protecting Against Cyber Threats

In an age of increasing cyber threats, MRP software must be fortified against potential breaches. Proactive measures, including regular software updates, employee training, and collaboration with cybersecurity experts, are essential.

XVIII. Industry 4.0 and MRP

MRP in the Era of Smart Manufacturing

Industry 4.0 heralds a new era of smart manufacturing, where MRP software integrates with technologies like the Internet of Things (IoT) and automation, creating a more interconnected and responsive production ecosystem.

Interconnectivity and Automation

The interconnectivity of machines and systems in Industry 4.0 enhances the automation capabilities of MRP software, allowing for more precise control, predictive maintenance, and a reduction in manual intervention.

XIX. The Human Element in MRP

Role of Employees in MRP Implementation

While MRP software automates many processes, the human element remains irreplaceable. The active involvement and expertise of employees are crucial during the implementation phase and in ongoing operations.

Balancing Automation with Human Expertise

Finding the right balance between automation and human expertise is an ongoing challenge. Businesses must leverage the strengths of MRP software while valuing the creativity, critical thinking, and problem-solving skills that humans bring to the table.

XX. Conclusion

Recap of Key Points

In conclusion, MRP software stands as a testament to the evolution of manufacturing and resource planning. From its humble beginnings to its integration with cutting-edge technologies, MRP software continues to be a driving force behind efficient, cost-effective, and sustainable business operations.

Looking Ahead: MRP Software in the Future

As we gaze into the future, the trajectory of MRP software is clear – continued integration with emerging technologies, a sharper focus on sustainability, and an unwavering commitment to helping businesses navigate the complexities of the modern industrial landscape.

Material Requirements Planning (MRP) software, with its intricate dance of algorithms, real-time data, and human expertise, emerges as a cornerstone in the architecture of modern business. The evolution of MRP from its inception to the sophisticated systems of today mirrors the relentless drive of industries to enhance efficiency, reduce costs, and stay ahead in an ever-changing market.

Navigating the nuances of MRP software is akin to conducting a symphony where each instrument plays a crucial role in creating a harmonious production process. The benefits, challenges, and future trends outlined in this article shed light on the multifaceted nature of MRP software and its impact on businesses across diverse sectors.

As businesses stand at the crossroads of technology and industry, the choice to implement MRP software becomes a strategic decision. Whether in manufacturing, retail, healthcare, or aerospace, the principles of MRP software adapt to the unique needs of each industry, optimizing processes and fostering growth.

In the realm of MRP software, the human element remains integral. As businesses embrace the fourth industrial revolution and smart manufacturing, finding the delicate balance between automation and human expertise becomes paramount. The employees, with their insights, creativity, and adaptability, become the conductors of this technological symphony.

As we conclude this journey through the labyrinth of MRP software, the road ahead is illuminated with the promise of continued innovation. The fusion of AI, machine learning, and real-time data heralds a future where MRP software becomes not just a tool but a strategic partner in the success of businesses worldwide.